NANHAI PNEUMATIC FENDER

Sling Type Pneumatic Fender

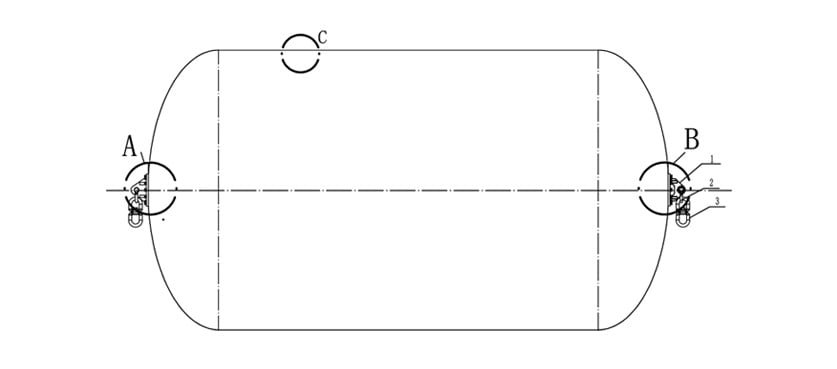

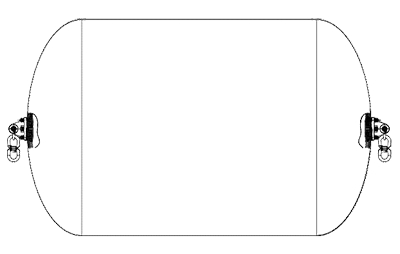

Sling type pneumatic fender is without chain tire net compare to Net type pneumatic fender. Its advantage is lighter weight and easier operation. Sling type pneumatic fender also have different initial internal pressure in 50kPa and 80kPa which manufactured should be according to ISO 17357-1:2014.

Sling type pneumatic fender Diameter from 0.5m-4.5m, Length from 1m-12m. Above 2.5m diameter fender will equipped safety valve. Traditional pneumatic fender structure has outer rubber layer part,synthetic tire cord part and inner rubber layer part. Based on actual application scenarios and improving the safety factor, NANHAI not only strives for perfection in raw materials, but also optimizes the structure and production technology to make it have higher safety and reliability.

Nearly 20 years of R&D and production of pneumatic fenders, adhering to the spirit of craftsmanship, focusing on details, pursuing excellence no matter where customers can see or not, in order to make better products.

NANHAI PNEUMATIC FENDER

Pneumatic Fender Classification

Pneumatic Fender Series: Sling Type I Chain Tyre Net Type I Hydro Pneumatic Fender.

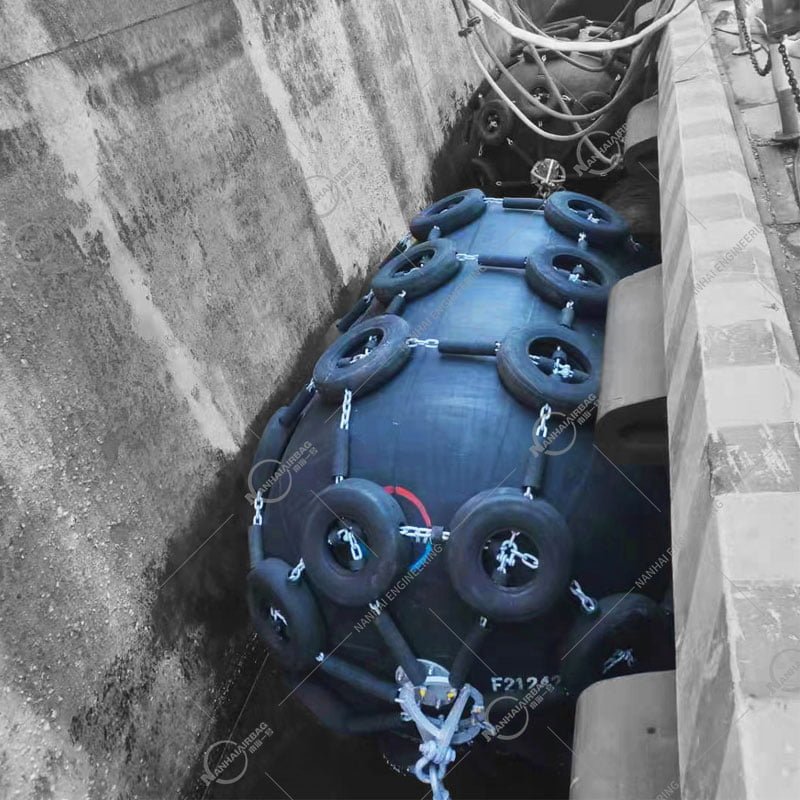

Pneumatic Fender-Heavy Duty Chain Tyre Net Type

- Initial internal pressure 50kPa/80kPa

- Diameter:500-5000mm (Fender Body Only)

- Length:500-9000mm (Fender Body Only)

- Truck/Aircraft Tires Optional

- Diameter ≥ 2500mm equipped with safety vlave

Hydro Pneumatic Fender

The Hydro pneumatic Fender is a special version of the Pneumatic Fender developed for submarines. Hydro pneumatic Fenders are partially filled with water and air and are equipped with a counterweight in order to keep them in a vertical position. This ensures that the submerged hull is properly protected by the fender at all times.Know More...

NANHAI PNEUMATIC FENDER

Advantages and Benefits

“Invisible Sight” still maintain ingenuity. NANHAI always insists on producing advanced quality products to fully protect the safety of hulls.

NANHAI PNEUMATIC FENDER

Unique Fender Structure

Pneumatic Fender Structure Fender Body Structure I Chain Tyre Net Structure

Basic pneumatic fender body construction consists of three parts: Outer rubber layer part, Cord layers part and inner rubber layer part. On the basis of the normal fender structure, NANHAI innovates and upgrades fenders, optimizes the structure to four parts,an air-tightness layer part is added (Reinforcement Layer Part).Greatly improved the airtightness performance and strength of pneumatic fender.

I Mechanical protection (Friction)

I Chemical Resistance (Environment)

I Energy dissipation

I Carry load of membrane force

I Keep the geometry stable

I Adhesion to reinforcement material

I Distance layer of fabric plies

I Shearing force loading

I Strengthen air tightness

I Reinforces rubber & tire cord plies

I Pressure transfer

I Ensure air tightness

I Provides chemical resistance

NANHAI PNEUMATIC FENDER

Advantage Analysis Report

which is helpful for users to quickly and accurately understand market products.

High Strength Tire Cord Material

The strength of pneumatic fender mainly comes from synthetic tire cord layer. NANHAI adopt 3-Strands tire (General adopt 2-Strands) as skeleton material to ensure fender strength.“Invisible Sight” NANHAI still maintain ingenuity. Provide high-strength support and bearing force for fenders.

Safety Valve Structure

Unreasonable safety valve design cannot quickly release pressure in emergency situations, which can easily lead to serious consequences of fender bursting. NANHAI self-developed and designed safety valve has a number of unique patents, as a vital insurance measure which can quickly and accurately release pressure in emergency situations.

Chain Tire Net Structure

Pneumatic fender chain tire net has many difference in design and structure, but the reasonable structure design and quality of all accessories determines whether the fender under truly protected. NANHAI chain tire net arrangement even and reasonable no matter fender head or body.Net density reach at least 70% of fender.

Combined Inflatable Valve

Diameter is bigger,at least 50% increase in inflation efficiency. More importantly,even if valve core is damaged due to improper operation by the user, it is only necessary to replace the top accessories.The design and structure of inflation valve are often overlooked by users.Once the inflation valve is damaged (One-piece Inflatable Valve Structure), fender will be unusable any longer.

Pneumatic fenders developed in 1950s, with a history of more than 60 years, NANHAI has been deeply engaged in the field of pneumatic fenders for nearly 20 years. In the past 20 years, continued to focus on the production crafts and continuously improve the performance of fenders, thus deriving THIRD- GENERATION of fender products and applying them to market.

For the THIRD-GNERATION pneumatic fender of NANHAI, we compared and analyzed them with various products on the market, and summarized the "NANHAI Pneumatic Fender Advantage Analysis", which is helpful for users to quickly and accurately understand market products.

NANHAI PNEUMATIC FENDER

Selected References

Parts of Pneumatic fender projects. If want to know more,please contact us.

NANHAI PNEUMATIC FENDER

Cooperation Partner

NANHAI sales network covers more than 70 countries from 7 continents, and has been highly praised by the market and customers. Which has become a world-class leading manufacturer of pneumatic fenders.

NANHAI PNEUMATIC FENDER

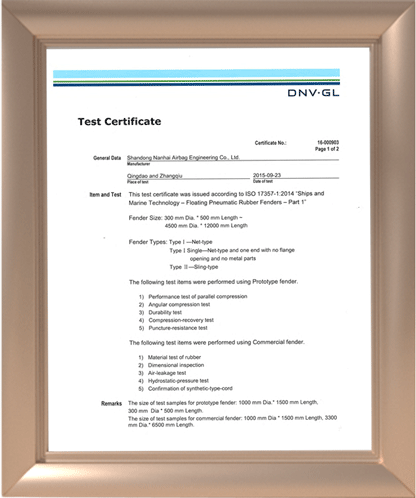

Certifications

DNV-GL ISO17357-1:2014

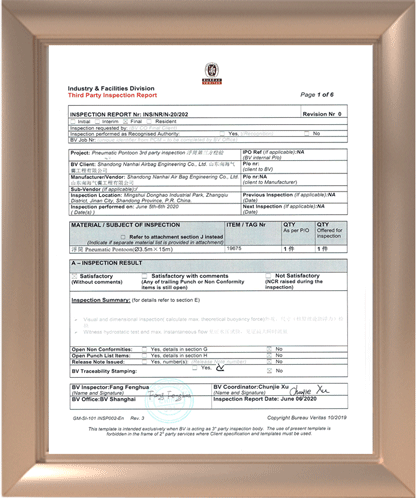

BV (Bureau Veritas)

ABS (American Bureau of Shipping)

LR (Lloyd's Register)

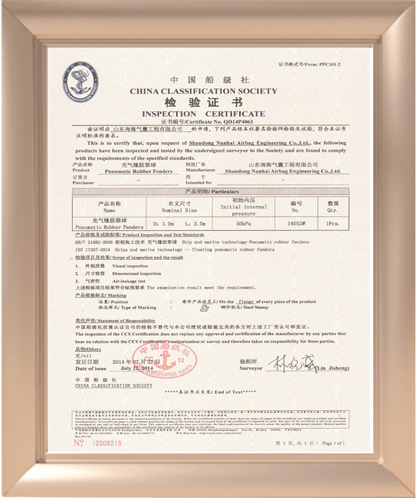

CCS (China Classification Society)

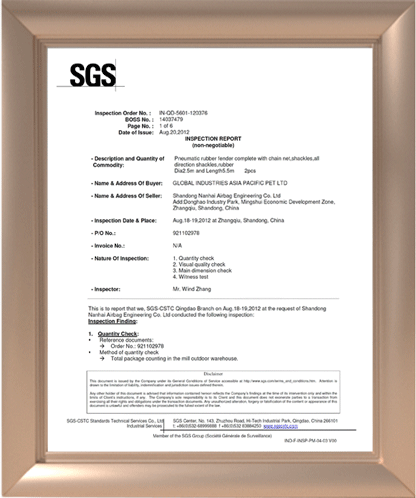

SGS