NANHAI Yokohama Fender

Floating pneumatic rubber fenders are known as Marine pneumatic rubber fenders(Marine rubber fenders), floating pneumatic rubber fenders (pneumatic fenders) or Yokohama-type pneumatic fenders( Yokohama fenders). NANHAI yokohama fender is structurally divided into NET TYPE PNUEMATIC FENDER, SLING TYPE PNUEMATIC FENDER, HYDRO PNUEMATIC FENDER, RIBBED PNUEMATIC FENDER, and CUSTOMIZED PNUEMATIC FENDER(customizable sizes, colors, Custom yokohama fender for performance levels).

The construction of floating pneumatic rubber fenders typically involves using a synthetic-cord-reinforced rubber sheet with compressed air inside. This design enables the fenders to provide effective protection and cushioning for ships, boats, vessels and docks during berthing and mooring operations. The presence of compressed air enables the fenders to float on the water surface and act as shock absorbers between two ships (ship-to-ship) or between a ship and a berth structure, effectively reducing the impact forces during berthing and mooring processes. The compressed air inside the fenders provides efficient cushioning, reducing the impact force when ships berth. The synthetic fiber-reinforced rubber sheets have high wear resistance and durability, ensuring long-term reliability.

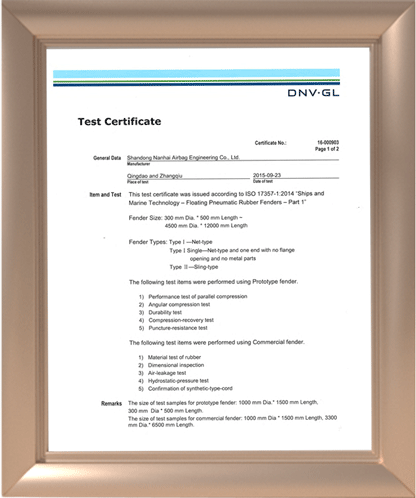

All Nanhai Marine Yokohama type floating pneumatic rubber fenders are manufactured full compliance with ISO 17357. Safety factor of NANHAI pneumatic fender far exceed the ISO 17357 requirements. NANHAI pneumatic fenders are divided into 4 grades (S, P, E, B) according to different application scenario.Above 4 grades all compliant with ISO17357. Taking “P Type” as an example (Pneumaitc Fender3300mm*6500mm) comprehensive performance is 50%-60% higher than ISO 17357 requirements, If you want to know more, please contact us for more info. download our PDF.

Above 4 grades all compliant with ISO 17357. Taking “P Type” as an example (Pneumatic Fender 3300mm*6500mm) comprehensive performance is 50%-60% higher than ISO 17357 requirements, If you want to know more, please contact us for more info.

M NHP-S-4P2S

Integrated valve system make operation more convenient.

M NHP-P-4P2S

Suitable for heavy duty STS/ berthing operations.

M NHP-E-4P2S

Suitable for general STS/ berthing operations.

M NHP-B-4P2S

Suitable for light duty STS/ berthing operations.

M NHP-SP-4P2S

Fender with light weight and easily transport and operate.

Pneumatic Rubber Fender Classification

Pneumatic Rubber Fender Initial Pressure

There are two initial pressure rating for NANHAI Pneumatic Rubber Fenders

- Pneumatic 50 (P50, Initial internal pressure 50kPa)

- Pneumatic 80 (P80, Initial internal pressure 80kPa)

Pneumatic Rubber Fender Types

Why Choose NANHAI

NANHAI Pneumatic Fender Structure

Basic pneumatic fender body construction consists of three parts: Outer rubber layer part, Cord layers part and inner rubber layer part. On the basis of the normal fender structure, NANHAI innovates and upgrades fenders, optimizes the structure to four parts: Outer rubber layer part, Synthetic tire cord layer part, Air tightness layer part, inner rubber layer part. Greatly improved the airtightness performance and strength of pneumatic fender.

1. Outer Rubber Layer Part

- Mechanical protection (Friction)

- Chemical Resistance (Environment)

- Energy dissipation

2. Synthetic Tire Cord Layer Part

- Carry load of membrane force

- Keep the geometry stable

3. Air Tightness Layer Part

- Strengthen air tightness

- Reinforces rubber & tire cord plies

4. Inner Rubber Layer Part

- Pressure transfer

- Ensure air tightness

- Provides chemical resistance

NANHAI Pneumatic Fender Performance Advantage

NANHAI Pneumatic Fender Quality Advantage

Compared to the traditional pneumatic fender 3 layers parts, the NANHAI pneumatic fender has a total of 4 layers parts.

Traditional pneumatic fender construction consists of outer rubber layer part, cord layer part, inner rubber layer part. NANHAI pneumatic fender construction consists of outer rubber layer part, synthetic tire cord layer part, air-tightness layer part and inner rubber layer part.

The synthetic tire cord structure uniquely designed by NANHAI marine fender engineers.

NANHAI: Only have two parts make one complete cycle,large over laparea,ensure reinforcement cord layer and complete fender performance.

Normal Type:Two parts as well, but less over lap area, low production cost but hardly ensure reinforcement cord layer performance.

Molded Type: At least four parts to make one complete circle, meanwhile no overlap area,which means there are at least four easy breaking points. The strength of fender mainly comes from the synthetic tire cord, so the synthetic tire cord structure and material of the fender play a crucial role.

Optimization of rubber materials based on ISO17357 provides guidance data.

An important research project of NANHAI professional rubber R&D team named "Temperature Zone Effect Project".According to the global temperature zone division (Tropical,Temperate zone,Frigid zone), different rubber formulations are developed, so that the production of pneumatic fender can maintain the best performance in each temperature zone.The results of this research project are gradually being applied to production manufactured.

Adopt 3-strand synthetic tire cord (Normal 2-strand).

Synthetic tire cord as an important skeleton material,have been proven to provide strong efficient reinforcement layers in fenders. Synthetic tire cord physical properties also determine the strength of fender, which is an important part that cannot be ignored. In the production of fender, the performance of two-strand tire and the three-strand tire is very different in synthetic tire cord. The physical properties of three-strand tire are much higher than two-strand tire to ensure the performance of fender.

Heavy duty inner and outer flange system.

There are many difference in design of flange system, including:safety performance,style design,material, size,bolts quantity etc.These aspect are all factors which affect the performance of pneumatic fender.

Self-developed safety valve with numbers patents.

The inflation valve is used to inflate and measure fender internal pressure. Many difference in valve design and structure,The quality of its structural design has been proved in many applications.

Normal Type: Small safety valve,during emergency situation ineffective in releasing excess internal pressure.

NANHAI: Excellent larger structural design, efficient and fast to release internal pressure.

NANHAI pneumatic fender safety completely Fender covered with heavy-duty chain tyre net.

Chain tyre net function is to protect fender and carry weight of fender, so as to prolong the service life of fender. The CTN is composed of chains, tyres (truck tyre/aircraft tyre),rubber sleeve, shackles, flange cages, towing rings, etc. Pneumatic fender chain tyre net has many difference in design and structure, but the reasonable structure design and quality of all accessories determines whether the fender under truly protected.

Different performance types and construction types can be selected, and different sizes and colors can be formulated according to the needs of customers.

NANHAI supports personalized customization, NANHAI team will be for your specific environment needs, to develop a suitable solution, which includes pneumatic performance type selection, pneumatic structure type selection, pneumatic size selection, pneumatic color selection. Help you find the right pneumatic rubber fender (pneumatic price and pneumatic quality)

Pneumatic fenders developed in 1950s, with a history of more than 60 years, NANHAI has been deeply engaged in the field of pneumatic fenders for nearly 20 years. In the past 20 years, continued to focus on the production crafts and continuously improve the performance of fenders, thus deriving THIRD- GENERATION of fender products and applying them to market.

For the THIRD-GNERATION pneumatic fender of NANHAI, we compared and analyzed them with various products on the market, and summarized the "NANHAI Pneumatic Fender Advantage Analysis", which is helpful for users to quickly and accurately understand market products.

How To Choose Fender

Ship to Ship Operations

Fill Out the Form: Fill out the pneumatic fender selection form based on the types, sizes, and weather conditions of the two ships.

Technical Advice: After submitting the form, our technical team will recommend the appropriate fender model based on the provided information.

Installation and Use: Follow the technical team's recommendations to install the pneumatic fenders, ensuring optimal cushioning protection during ship-to-ship operations.

Ship to Jetty Operations

Design Parameters: The selection of pneumatic fenders is based on multiple design parameters of each ship's berthing and mooring conditions.

Contact Technical Team: If you have specific requirements, please contact our technical team.

Solution Provision: Our technical team will provide suitable solutions based on your needs and the specific conditions of the jetty.

Installation and Use: Install the pneumatic fenders according to the provided solutions to ensure effective protection and cushioning during jetty operations.

Submarine Operations

Specific Needs: Choose the appropriate pneumatic fenders based on the unique needs and operational environment of the submarine.

Technical Support: Contact our technical team, who will provide professional fender solutions for submarine operations.

Installation and Use: Ensure that suitable pneumatic fenders are used during submarine berthing and operations to provide necessary cushioning protection.

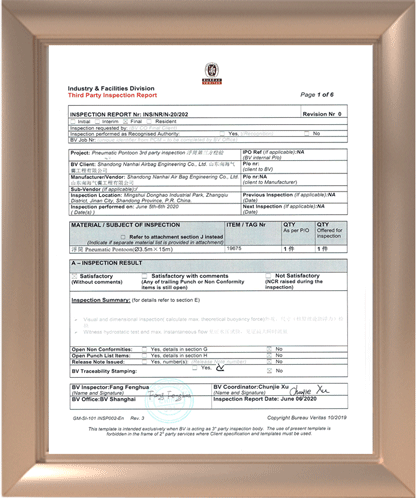

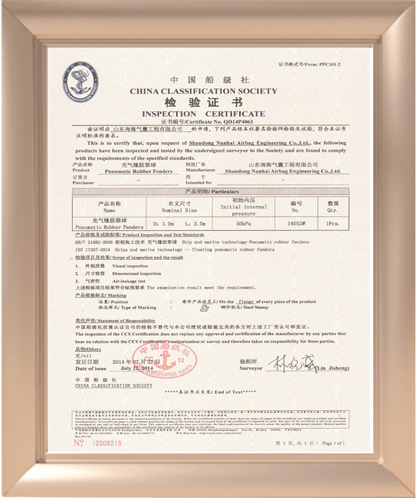

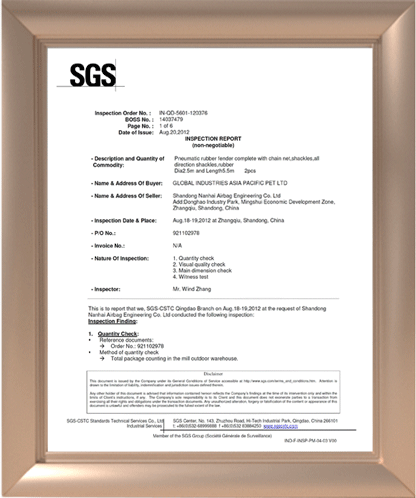

NANHAI pneumatic Fender Certificate,Cooperation Partner &Related Resources

NANHAI pneumatic Fender Certificate

NANHAI pneumatic Fender Related Resources

NANHAI Pneumatic Fender Cooperation Partner

NANHAI is a trusted supplier of marine fender and marine airbag. We have cooperated with Marine equipment related enterprises many times, the following is the trademark of the cooperative enterprise