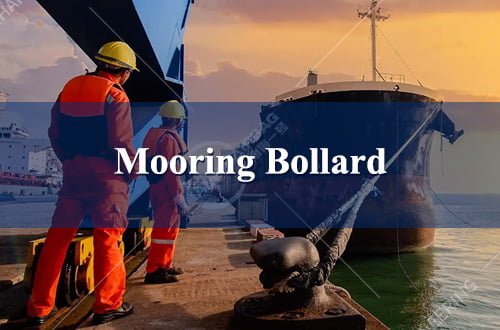

Marine Mooring Bollard Types | Various, High Quality

port infrastructure is of vital importance for coastal cities or wharves, so we offer you many types of Mooring bollards to choose from. Moreover, NANHAI's biggest advantage is its resolute quality assurance advantage.(P) All bollard is made of SG ductile cast iron or cast steel material.The following corrosion protection systems are offered: premiered only, painted with primer and 2-component epoxy layer & topcoat, galvanized, galvanized and painted .

Simple Structure Mooring Post

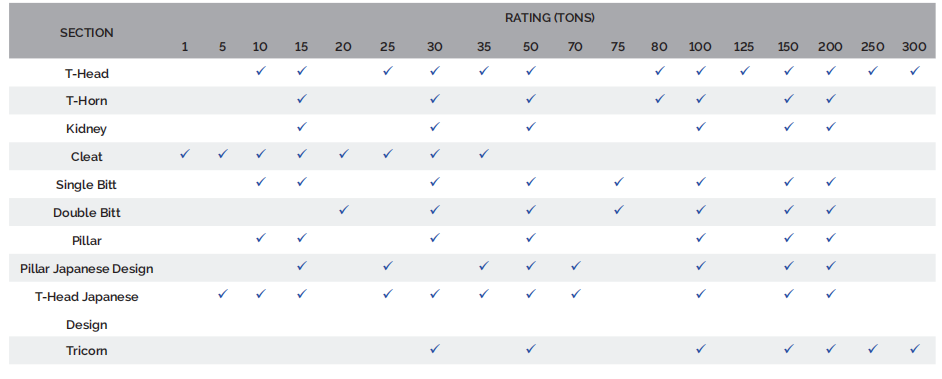

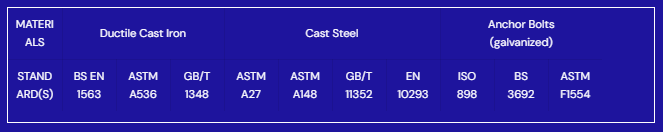

Standard Range&Material Specification Certificate

|WHY CHOOSE NANHAI BOLLARDS

NANHAI Mooring Bollard Standard Range

Boolard Material Specification Certificate

All the marine mooring bollards supplied by NANHAI meet the highest standard and strictlycontrol the export quality of marine mooring bollards from China.

BOLLARD SELECTION & LAYOUT

| How to choose bollard

Bollards should be designed and laid out according to local standards.

When designing bollards, it's essential to adhere to local standards to ensure safety and compliance. Properly designed and strategically placed bollards are crucial for effective mooring operations.

Some of the following aspects are to be considered in the design of the berth:

-

Mooring patterns and line types, sizes, and angles

Evaluate the mooring patterns, types of lines, their sizes, and angles to ensure optimal bollard performance. -

Changes in draft during loading/unloading of the vessel

Consider the changes in draft that occur during vessel loading and unloading, which can affect the tension and alignment of mooring lines. -

Wind and current forces

Design bollards to withstand wind and current forces, ensuring stability under various environmental conditions. -

Swell, wave, and tidal forces

Account for swell, wave, and tidal forces that can exert additional pressure on mooring lines and bollards. -

Other abnormal environmental loadings

Prepare for abnormal environmental loadings that could affect the bollard's performance, such as extreme weather events.

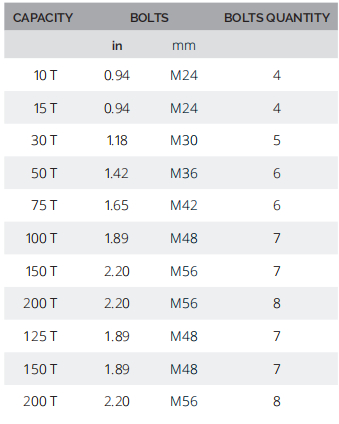

Mooring loads should be calculated where possible, but the following table can be used as an approximate guideline, also noting that if the berth is expected to experience adverse weather conditions, the bollard capacity should be increased by 25% or greater. Precise mooring load calculations are recommended, but in the absence of detailed calculations, the following guidelines offer a rough estimate. If the berth is subject to adverse weather conditions, consider increasing the bollard capacity by 25% or more.

NANHAI bollards can cope with horizontal angles of ± 90° (except for pillar bollards, which is in all horizontal angles) and vertical angles up to 60° depending on bollard type. NANHAI bollards are versatile, handling horizontal angles of ± 90° and vertical angles up to 60°, depending on the bollard type. Pillar bollards can accommodate all horizontal angles, offering flexibility in various mooring scenarios.

Design codes recommend that bollards are frequently placed at 15-30m intervals, often at the same spacing as fenders (either at the same point as fenders or midway). Another approximate guide is 15% of the length of the shortest ship. Bollard placement is critical for effective mooring. Design codes suggest placing bollards at 15-30 meter intervals, often matching the spacing of fenders. Bollards can be placed either at the same point as fenders or midway. Alternatively, an approximate guide is to space bollards at 15% of the length of the shortest ship expected at the berth.

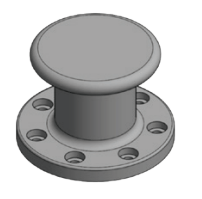

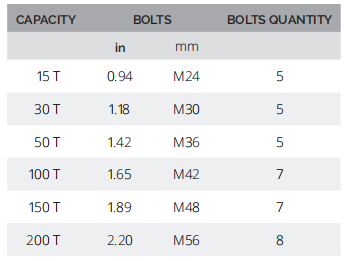

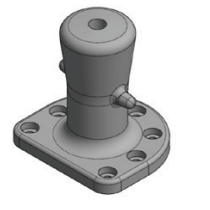

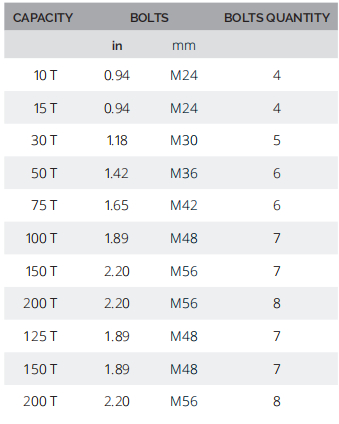

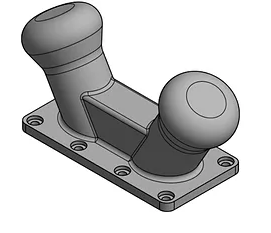

NANHAI Pillar Mooring Bollards

| Structure, Capacity Range, Line Loading Range

Tee Mooring Bollards so known as Tee bollards or Tee-Head Dock bollards, is a specially-designed marine bollard for carrying wire ropes. The bollard has a “T” shaped top, a simple and efficient shape for securing marine vessels to a wharf, and is suitable for steeper rope angles.The general recommended line angle is +75 degree to -15 degree.and we support10T-300T

- Capacity Range

- 10-200 Metric Tons

- Line Loading Range

- ±360° horizontal

- +60°/-15° vertical

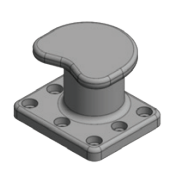

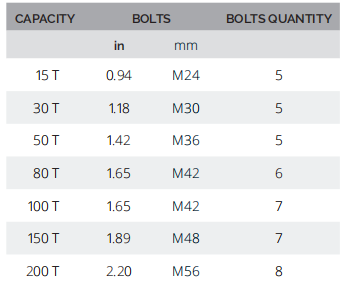

NANHAI Kidney Mooring Bollards

| Structure, Capacity Range, Line Loading Range

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

- Capacity Range

- 15-200 Metric Tons

- Line Loading Range

- ±180° horizontal

- +75°/-15° vertical

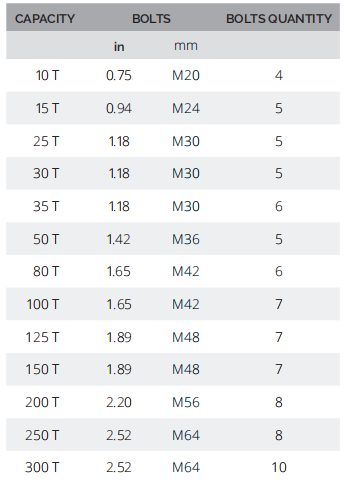

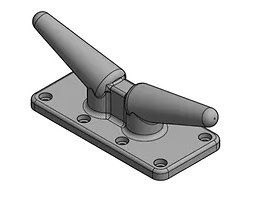

NANHAI Tee Mooring Bollards

| Structure, Capacity Range, Line Loading Range

Tee Mooring Bollards so known as Tee bollards or Tee-Head Dock bollards, is a specially-designed marine bollard for carrying wire ropes. The bollard has a “T” shaped top, a simple and efficient shape for securing marine vessels to a wharf, and is suitable for steeper rope angles.The general recommended line angle is +75 degree to -15 degree.and we support10T-300T

- Capacity Range

- 10-200 Metric Tons

- Line Loading Range

- ±180° horizontal

- +60°/-15° vertical

NANHAI Single Bitt Bollards

| Structure, Capacity Range, Line Loading Range

Single Bitt Bollards consist of a solid horseshoe shape at the bottom, with a cylinder wide at the top and narrow at the bottom, but with two "ears" at the waist of the cylinder. It is well suited for berths with large tidal ranges and for steep mooring angles. This configuration is especially popular in North America and can be utilised simultaneously with multiple mooring lines.

- Capacity Range

- 10-200 Metric Tons

- Line Loading Range

- ±180° horizontal

- +75°/-15° vertical

NANHAI Staghorn Bollards( Double horn bollard )

| Structure, Capacity Range, Line Loading Range

Staghorn bollards often referred to as twin horn dock bollards or double horn bollards, are particularly suitable for applications where tidal range variations are large and can handle steep mooring line angles. They are also capable of accepting multiple mooring lines due to their complex profile. The staghorn dock bollard (or twin horn dock bollard) is also supplied with different base types, such as hexagon type base, round type base, square type base and semi-circle type base, which can be confirmed by the concrete of the dock, port or jetty design and application environment.

- Capacity Range

- 15-200 Metric Tons

- Line Loading Range

- ±180° horizontal

- +75°/-15° vertical

NANHAI Single Bitt Bollards

| Structure, Capacity Range, Line Loading Range

Single Bitt Bollards consist of a solid horseshoe shape at the bottom, with a cylinder wide at the top and narrow at the bottom, but with two "ears" at the waist of the cylinder. It is well suited for berths with large tidal ranges and for steep mooring angles. This configuration is especially popular in North America and can be utilised simultaneously with multiple mooring lines.

- Capacity Range

- 1-35 Metric Tons

- Line Loading Range

- ±180° horizontal

- +60°/-15° vertical

NANHAI Double Bitt Bollards

| Structure, Capacity Range, Line Loading Range

Double bitt bollards, also known as twin post bollards or twin bitt bollards, are specifically designed for demanding mooring applications, particularly in ports with significant tidal variations. These bollards are engineered to handle heavy loads and can accommodate multiple mooring lines simultaneously due to their robust twin-post profile. Their narrow base footprint makes them ideal for installation in confined spaces on wharves with limited work areas. These bollards are capable of supporting loads ranging from 15T to 200T.

-

Capacity Range

-

20-200 Metric Tons

-

Line Loading Range

-

±180° horizontal

-

+60°/-15° vertical

NANHAI offers a full range of Mooring Bollards

NANHAI Product Related Products

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Port Infrastructure, Floating Technology, Ship to Ship, Marine Prevention, Shipyard Solution, Offshore Project etc.

.png)