NANHAI Pneumatic Fender Introduction

Pneumatic fender have different initial internal pressure in 50kPa and 80kPa which manufactured should be according to ISO 17357-1:2014.Traditional pneumatic fender structure has outer rubber layer part,synthetic tire cord part and inner rubber layer part. Based on actual application scenarios and improving the safety factor, NANHAI not only strives for perfection in raw materials, but also optimizes the structure and production technology to make it have higher safety and reliability.

NANHAI Pneumatic Fender adapts well to extreme environments. It operates stably at -50°C and below, and its core performance remains unaffected even in harsh weather like heavy snow or strong winds. It delivers reliable performance for use in frigid high-latitude areas or low-temperature scenarios, overcoming the limitations that low temperatures impose on equipment.

Nearly 20 years of R&D and production of pneumatic fenders, adhering to the spirit of craftsmanship, focusing on details, pursuing excellence no matter where customers can see or not, in order to make better products.

NANHAI | EUDR-Compliant, Green-Certified (Sept 29, 2025)

100% EUDR-Aligned: Strictly complies with EU Deforestation-free Regulation, with full supply chain traceability.

Uncompromised Performance: Ensures core product performance while meeting compliance, adaptable to various harsh and extreme environments.

NANHAI Pneumatic Fender Characteristics

Adopt world today leading & professional high-tech raw materials and unique production technology to deliver a lifetime of reliable performance which have been applied in various extreme environments.

Manufacturing Experience

20 Years

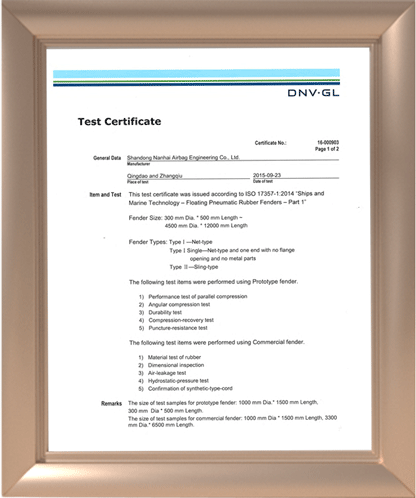

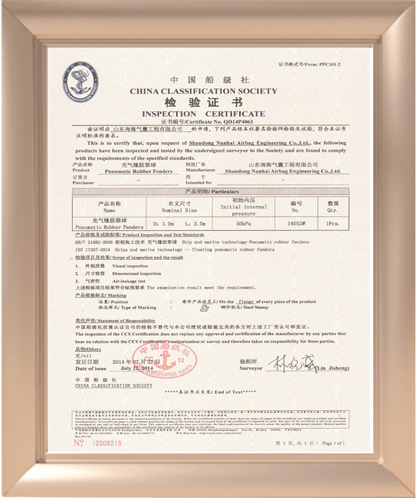

Manufacturing Standard

ISO 17357-1:2014

Safety Factor

Exceed 7 Times

Compression Rate

70%-80%

Withstands cold & harsh weather

-50°C & below

Tyre Net Density

Exceed 70%

Fender Size & Color

Customized

Inclined Berthing

✓

Soft Reaction

✓

Lower Mooring Force

✓

Shearing Force Absorbed

✓

Tide Adaptable

✓

Easier Installation

✓

Low Maintenance Cost

✓

NANHAI Pneumatic Fender Classification

Chain Tire Net

Yes

Tire Optional

Truck/Aircraft Tire

Internal Pressure

50kPa, 80kPa

Diameter Range

300mm-4,700mm

Length Range

500mm-12,000mm

Color Optional

Black, Red, Grey, White

Chain Tire Net

No

Tire Optional

No

Internal Pressure

50kPa, 80kPa

Diameter Range

300mm-4,700mm

Length Range

500mm-12,000mm

Color Optional

Black, Red, Grey, White

Chain Tire Net

No

Tire Optional

No

Internal Pressure

50kPa, 80kPa

Diameter Range

2000mm-4,500mm

Length Range

6,000mm-9000mm

Color Optional

Black, Red, Grey, White

NANHAI Pneumatic Fender Construction

Basic pneumatic fender construction consists of three parts: Outer rubber layer part, cord layers part and inner rubber layer part. On the basis of the normal fender structure, NANHAI innovates and upgrades fenders, optimizes the structure to four parts, an air-tightness layer part is added (Reinforcement Layer Part). Greatly improved the airtightness performance and strength of pneumatic fender.

Outer Rubber Layer Part

- Mechanical protection (Friction)

- Chemical Resistance (Environment)

- Energy dissipation

Synthetic Tire Cord Layer Part

- Carry load of membrane force

- Keep the geometry stable

Air Tightness Layer Part

- Strengthen air tightness

- Reinforces rubber & tire cord plies

Inner Rubber Layer Part

- Pressure transfer

- Ensure air tightness

- Provides chemical resistance

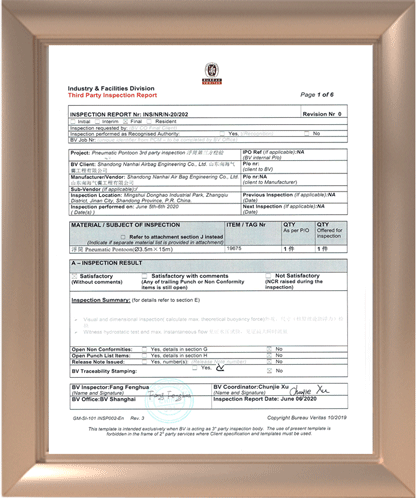

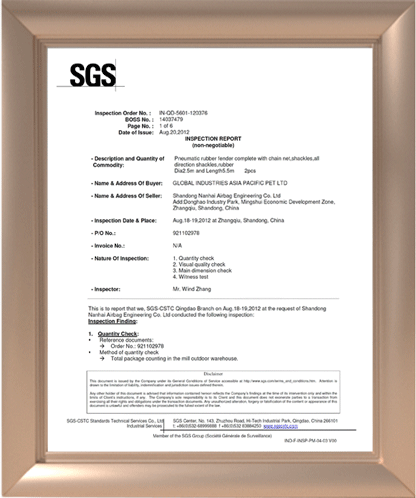

Specifications and Related Resources

NANHAI Pneumatic Fender Selected References

Parts of Pneumatic fender projects. If want to know more,please contact us.

NANHAI Pneumatic Fender Cooperation Partner

NANHAI sales network covers more than 70 countries from 7 continents, and has been highly praised by the market and customers. Which has become a world-class leading manufacturer of pneumatic fenders.