Rolling Fenders

The Rolling Fender is generally built from an energy absorbing elastomer unit which is mounted onto a single rotating shaft. This unit is designed with maintenance-free bearings, typically from stainless steel, and composite material. Mounted into a steel casing it can rotate freely. The main purpose of Rolling Fenders is to act as a guiding system for a smooth and safe passage.

Rolling Fenders can be installed in various combinations such as

- Stacked double or triple fender to cover larger heights in tidal areas

- Side by side to guide the vessel through a narrow passage

- Installed with an angle to cater for flare angles of the vessel hull

Rolling Fenders come in certain standard sizes but typically each project requires a unique design. NANHAI is available in a variety of custom sizes.

NANHAI | EUDR-Compliant, Green-Certified (Sept 29, 2025)

100% EUDR-Aligned: Strictly complies with EU Deforestation-free Regulation, with full supply chain traceability.

Uncompromised Performance: Ensures core product performance while meeting compliance, adaptable to various harsh and extreme environments.

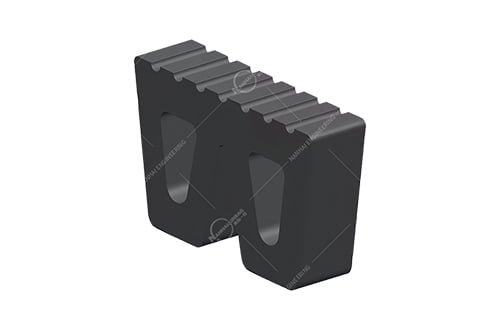

Roller Fender

Roller Fenders are commonly used on the berth corners and dock entrances.Roller Fenders are usually installed to guide ships in restricted spaces like walls of dry docks and prevent hull damage.They can also be used on corners and lock entrances where lower energies are needed.

Roller Fenders use stainless steel and composite bearings which give a very low rolling resistance and require virtually zero maintenance.

- Highest energy absorption

- Gentle contact face

- Very low rolling resistance

- Use singly or in multiple stacks

- Composite and stainless steel bearings

- Low maintenance casing design

- Dry-dock entrances and walls

- Entrance to locks

- Other narrow or exposed areas

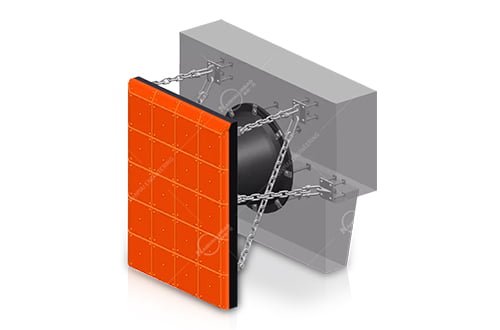

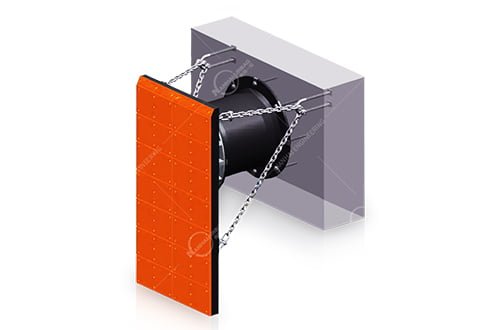

Wheel Fender

Wheel fenders are widely used on marine environments with exposed corners to help ships maneuver into berths and narrow channels such as locks.They are also widely installed along the walls of dry docks and other restricted channels to help guide vessels and prevent hull damage.

The main axle slides on bearings and the wheel reacts against back rollers to provide high energy and minimal rolling resistance, whilst the stainless steel and composite bearings are almost zero maintenance.

- Highest energy absorption

- Multipurpose use

- Use singly or in multiple stacks

- Guiding system & energy absorption

- Typically maintenance free

- No friction due to fender rotation

- Entrance to locks

- Dry-dock entrances and walls

- Exposed corners

- Other narrow or exposed areas

Cushion RollerS

Cushion Rollers are used to guide pontoons and fl oating structures quietly and gently up and down their guide piles. The resilient wheel can be supplemented by a rubber cushion pad to withstand berthing impacts.

The Cushion Roller is designed with typically maintenance-free bearings from stainless steel. The main purpose of Cushion Rollers is to guide pontoons and floating structures and to provide additional protection.

- Extremely quiet

- Rubber cushion to withstand berthing impacts

- Withstands berthing impacts

- Maintenance-free bearings

- Low maintenance bearings

- Pontoon pile guides

- Other floating structures

Related Products

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Port Infrastructure, Floating Technology, Ship to Ship, Marine Prevention, Shipyard Solution, Offshore Project etc.

Would you like to know more about Rubber Fender?

Contact us now!

NANHAI Other Marine Industrial Forms

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Berthing, Mooring, Ship to Ship, Ocean Wind Power, Deep-Sea Farming, Buoyancy and Salvage, Bridge Blocking, Ship Launching, Dock Caisson Moving etc.