NANHAI Ship Launching Airbag

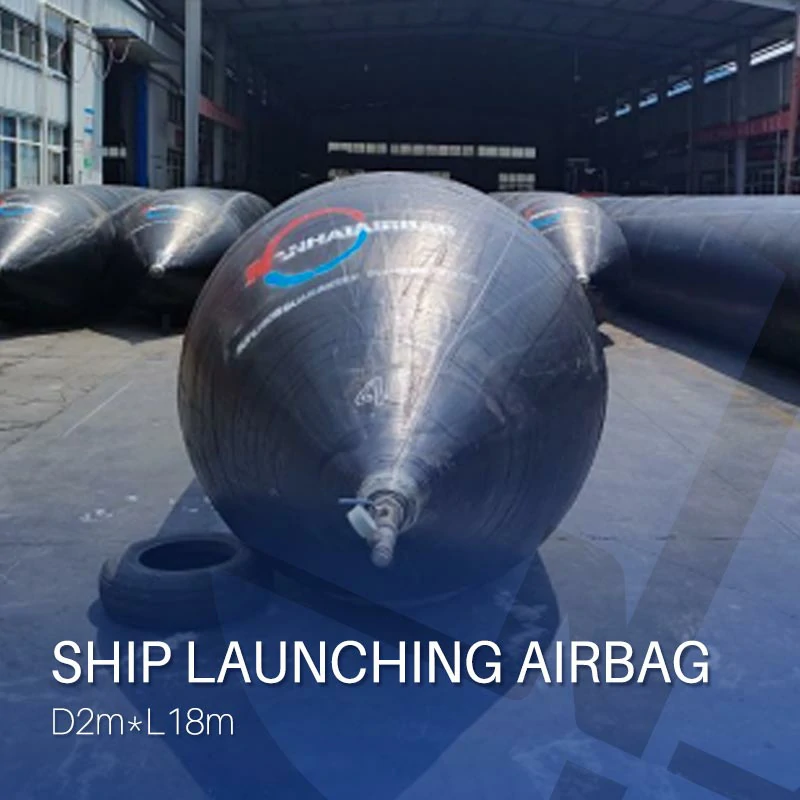

Nowadays with the improvement of production technology and raw materials, ship launching airbag can be used at the launching of larger vessels which could be reach DWT of 100,000 tonnes.

International Leading Ship Launching Airbag Manufacturer

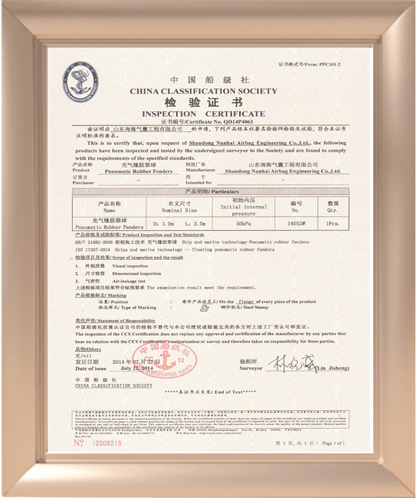

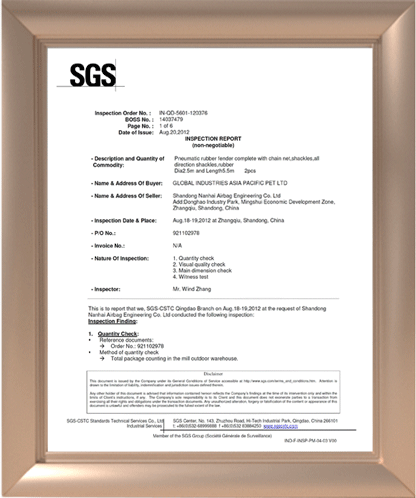

Nearly 20 years of R&D and production of ship launching airbag, adhering to the spirit of craftsmanship, focusing on details, pursuing excellence no matter where customers can see or not. NANHAI sales network covered more than 70 countries on 7 continents, and has been highly praised by the market and customers, become the world-class leading manufacturer of ship launching airbag (Marine Airbags).

Oversea Technical Support For Ship Launching Operation

NANHAI's after-sales service include the oversea technical support that guide customer how to operate launching ship. At present, NANHAI technical team has provided technical support in some countries in Southeast Asia, North Africa and South America. Specific information please contact us.

NANHAI provides the most convenient and economical ship launching products and technologies in the world. We has innovated ship launching airbag and world-leading production processes to ensure adequate safety performance. If you want to know more, please contact us for more info.

NANHAI | EUDR-Compliant, Green-Certified (Sept 29, 2025)

100% EUDR-Aligned: Strictly complies with EU Deforestation-free Regulation, with full supply chain traceability.

Uncompromised Performance: Ensures core product performance while meeting compliance, adaptable to various harsh and extreme environments.

BEENEST AIRBAG

An airbag which is not scratched and punctured

82% Increase

Puncture resistance is 82% higher than traditional airbags.

4.5 Times

4.5 times safety factor (Normal 3 times safety factor)

50% Off

Service life is doubled, the cost of application is reduced by 50%.Almost no maintenance required.

NANHAI Ship Launching Airbag Characteristics

Adopt world today leading & professional high-tech raw materials and unique production technology to deliver a lifetime of reliable performance which have been applied in various extreme environments.

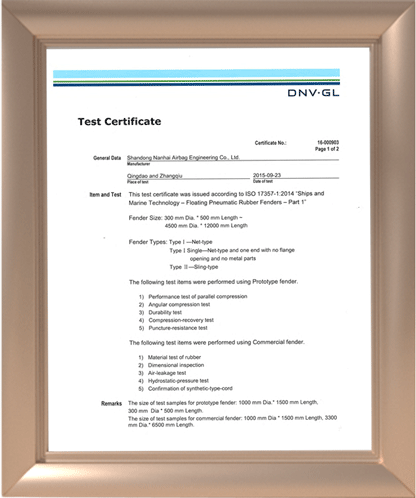

Manufacturing Experience

20 Years

Manufacturing Standard

ISO 14409

Safety Factor

Exceed 4.5 Times

Airbag Construction

4 Layer Parts Structure

Airbag Size & Model

Customized

Harshest Environments

✓

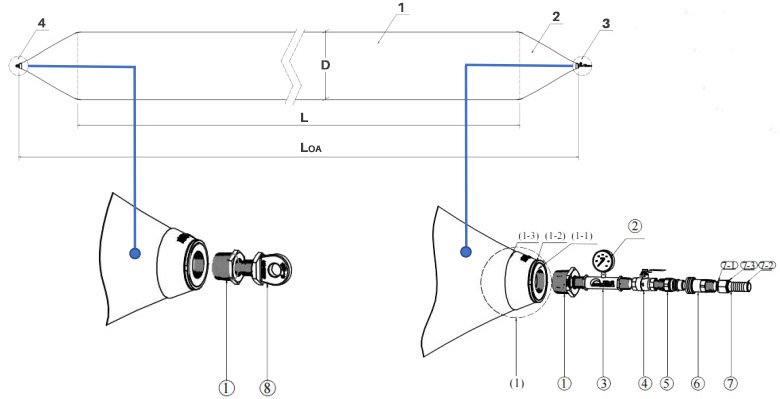

Stainless Steel Air Inflated Valve

✓

Production Process Upgrade

✓

Easier Installation

✓

Low Maintenance Cost

✓

NANHAI Ship Launching Airbags Selection

On-Site Technical Guidance Service, NANHAI technical team can go to the operating site to provide technical guidance and help customers with ship launching/upgarding operations. If you have requirements please contact us and our technical team will provide solutions.

NANHAI Ship Launching Airbag Construction

Normal airbag construction consists of outer rubber layer part, cord layers part and inner rubber layer part. On the basis of the normal airbag structure, NANHAI optimizes the production process, the Reinforcement Layer Part is added. Airbag shoulder is easily accessible part,enhanced protection and improved airbag safety.

Normal Ship Launching Airbag

Airbag shoulder is easily accessible and weakness part, normal structure hardly afford huge loading capacity. Because normal structure airbag head part and body part is separated, not one-piece structure, another reason have no reinforcement part.

NANHAI Superior Ship Launching Airbag

One-Piece structure production process, synthetic tire cord runs through the whole airbag, no weak point, stronger loading capacity. Meanwhile add reinforcements at the shoulder part, provides double insurance for airbag safety.

Outer Rubber Layer Part

- Mechanical protection (Friction)

- Chemical Resistance (Environment)

- Energy dissipation

Synthetic Tire Cord Layer Part

- Carry load of membrane force

- Keep the geometry stable

Reinforcement Layer Part

- Strengthen the wear resistance

- Reinforces rubber

Inner Rubber Layer Part

- Pressure transfer

- Ensure air tightness

- Provides chemical resistance

Specifications and Related Resources

NANHAI Ship Launching Airbag Selected Cases

Parts of Ship Launching Airbag projects. If want to know more,please contact us.

NANHAI Pneumatic Fender Cooperation Partner

NANHAI sales network covers more than 70 countries from 7 continents, and has been highly praised by the market and customers. Which has become a world-class leading manufacturer of pneumatic fenders.