NANHAI Ship Launching Airbag

BeeNest Airbag

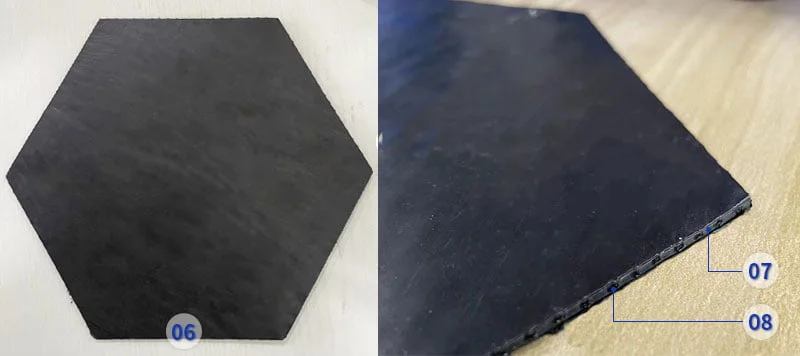

BeeNest Airbag is a unique patented product independently developed by NANHAI. BeeNest Airbag not only has all the advantages of NANHAI ship launching airbags, but also equipped a layer of high-strength anti-puncture composite material, which can effectively prevent accidental scratches and punctures caused by sharp objects, suitable for extremely harsh operating environments and improved the service life of the product significantly.

BeeNest Airbag after equipped with high-strength anti-puncture composite material, still can keep good flexible performance, extremely easy to operate on site.

NANHAI is the exclusive and NO.1 manufacturer of BeeNest Airbag in China, which is the first company upgrade traditional ship launching airbag to this unique airbag. BeeNest Airbag own world today leading & professional high-tech raw materials and unique production technology.

Please contact us for Ship Launching Airbags Brochure to know more information.

NANHAI | EUDR-Compliant, Green-Certified (Sept 29, 2025)

100% EUDR-Aligned: Strictly complies with EU Deforestation-free Regulation, with full supply chain traceability.

Uncompromised Performance: Ensures core product performance while meeting compliance, adaptable to various harsh and extreme environments.

NANHAI Ship Launching Airbag

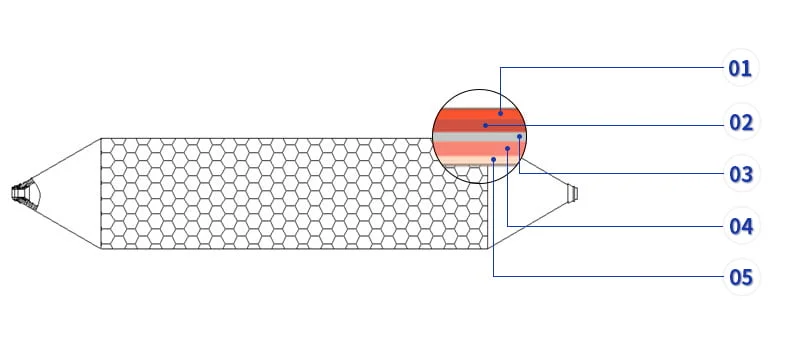

BeeNest Airbag Structure

BeeNest Airbags can reflect unparalleled performance, mainly due to this type airbag Excellent Structural Design, Superior Original Material and World-Leading Production Technology.

- ① Anti-puncture layer part

- ② Reinforcement layer part

- ③ Outer rubber layer part

- ④ High strength synthetic tire cord layer part

- ⑤ Inner rubber layer part

NANHAI Ship Launching Airbag

BeeNest Airbag Benefits

- Exclusive patented manufacturer.

- 100% Anti-punctured airbag.

- Suitable for extremely harsh operation environments.

- Good flexible performance.

- Longer service life.

- Various performance indicators far exceeded ISO14409

- Safety factor reach 4.5 times (Normal 2-3 times)

- Airbag body 5 parts structure (Normal 3 parts).

- Adopt 3-strand synthetic tire cord (Normal 2-strand).

- Built-in stainless steel air inflated valve.

- Talcum powder removal production process (Industry NO.1).

- Diameter from 300 mm to 4,000 mm.

- Length from 3,000 mm to 33,000 mm.

- Customized in various sizes.

NANHAI SHIP LAUNCHING AIRBAG

Supreme Production Crafte

Why some airbag looks dirty, like used one?

Rubber layer and tire cord layer are main raw materials of ship launching airbag. "Talcum Powder" is used in the production process by taking the advantages of slippery, soft and dry characteristics to prevent the adhesion between the layers and make it easier to operate and produce. But ignore the disadvantages to use "Talcum Powder" in the production process:

- 1.Insufficient bonding strength between each layer.

- 2.Airbag appearance looks dirty, like used one.

- 3.Poor Production Environment.

Unprecedented revolution in ship launching airbag industry.

NANHAI has nearly 20 years experience in airbag production and R&D, always uphold the persistent belief in high-quality products. Through continuous efforts, finally our technical team applied the "Talcum Powder Removal Technology" to airbag production process. The feasibility, safety and stability of the process were verified by repeated type tests. Products performance improved greatly.

NANHAI's subversive R&D capabilities and innovation capabilities have carried out an unprecedented "REVOLUTION" in the production process of airbags, and always maintained NO. 1 POSITION in the industry.

NANHAI SHIP LAUNCHING AIRBAG

Selected References

Parts of Ship Launching Airbag projects. If want to know more, please contact us.

Project Country: UAE

Year: 2022

Product: Ship Launching Airbag

Airbag Spec.: D1.8m*L30m, D1.8m*L24m, 8 Layers

Quantity: 15 Units

Project Country: Korea

Year: 2022

Product: Ship Launching Airbag

Airbag Spec.: D1.5m*L18m, D1.5m*L25m, D2m*L18m, 12 Layers

Quantity: 32 Units

Project Country: Iran

Year: 2023

Product: Ship Launching Airbag

Airbag Spec.: D1.5m*L27m, 10 Layers

Quantity: 21 Units

Project Country: Indonesia

Year: 2023

Product: Ship Launching Airbag

Airbag Spec.: D2m*L25m, D2m*L20m, D2m*L15m, 8 Layers, D1.8m*L15m,10 Layers

Quanity: 28 Units

Project Country: Singapore

Year: 2023

Product: Ship Launching Airbag

Airbag Spec.: D2m*L16m, D2m*D18m, 8 Layers

Quantity: 20 Units

Project Country: Canada

Year: 2023

Product: Ship Launching Airbag

Airbag Spec.: D1.5m*L23m, 10 Layers

Quantity: 22 Units

Project Country: Philippines

Year: 2022

Product: BeeNest Airbag

Airbag Spec.: D1.8m*L15m, D1.5m*L6m,9 Layers

Quantity: 15 Units

Project Country: UAE

Year: 2023

Product: Ship Launching Airbag

Airbag Spec.: D1.5m*L16m, 14 Layers, D1.5m*L16m,20 Layers

Quantity: 10 Units

NANHAI SHIP LAUNCHING AIRBAG

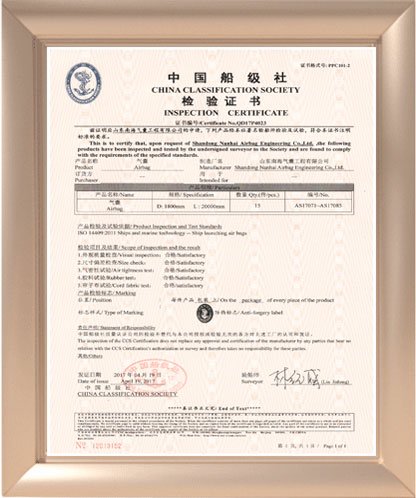

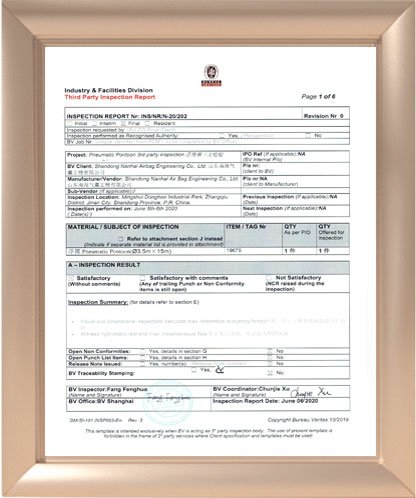

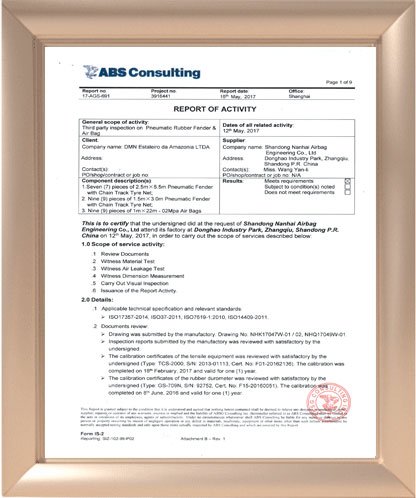

Certifications

NANHAI Product

Related Products

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Port Infrastructure, Floating Technology, Ship to Ship, Marine Prevention, Shipyard Solution, Offshore Project etc.