Ship Launching Airbags: The Game-Changing Tech Keeping Ships (and Budgets) Afloat

17/06/2025Super Cone Rubber Fenders: The Marine Industry’s Secret Weapon for Safer, Smarter Docking

25/06/2025

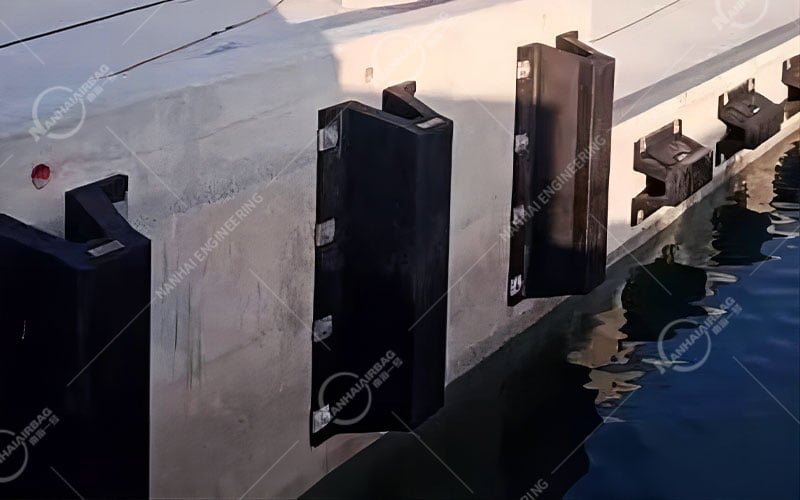

Ever watched a massive cargo ship edge toward a dock, heart racing as it inches closer to the pier? One wrong move, and boom—hull damage, costly repairs, port delays, or even environmental spills. That’s the reality of busy ports worldwide. But here’s the hero we need: super arch rubber fenders. These rugged, rubbery giants are rewriting the rules of collision protection, keeping ships, docks, and wallets safe. Let’s dive in.

🔍 Featured Snippet Alert: What Are Super Arch Rubber Fenders?

Super arch rubber fenders are heavy-duty, arched marine fenders designed to absorb and redirect kinetic energy during ship-to-dock or ship-to-ship collisions. Made from multi-layered marine-grade rubber, they feature a curved, “arched” shape that distributes impact forces evenly—preventing hull damage, reducing repair costs, and extending the lifespan of both vessels and port infrastructure. Commonly used in busy harbors, these fenders are a go-to for modern maritime safety.

Why This Matters: When Collisions Cost Millions (and Risk Lives)

Imagine a 20,000-ton container ship clipping a pier at 5 knots. The result? Bent railings, cracked hull plates, and a repair bill topping 500,000.Worse,spilledfuelcouldfoullocalwaters,leadingto100k+ in fines and years of ecological cleanup.

The Hidden Costs of Outdated Fenders

For years, ports relied on basic fenders like flat rubber pads or wooden logs. But these are no match for today’s larger, faster ships:

- Hull Damage: Rigid fenders crack under pressure, leaving ships vulnerable to water ingress.

- Dock Wear: Poor energy absorption means docks take the brunt of impacts, needing frequent repairs.

- Downtime: A single collision can shut down a dock for days, costing ports millions in lost revenue.

Take the Port of Rotterdam, Europe’s busiest hub: In 2021, a bulk carrier collided with an aging fender system, tearing a 3-meter gash in its side. Repairs took 2 weeks, costing the shipping company $1.2M. Meanwhile, ports using super arch rubber fenders report 70% fewer collision-related damages and 50% less downtime.

💡 How Do Super Arch Rubber Fenders Work? The Science of Safety

These aren’t your average rubber bumpers. Super arch fenders are engineering marvels built to handle extreme forces:

1. Arched Design for Force Distribution

The signature “arch” shape isn’t just for looks. It acts like a shock absorber, spreading impact energy across the fender’s surface instead of concentrating it in one spot. This reduces peak force by up to 60% compared to flat fenders.

2. Multi-Layered Rubber Construction

The outer layer is made from abrasion-resistant neoprene or EPDM rubber—tough enough to withstand scrapes from ship hulls. Beneath that, a dense layer of synthetic fabric (like polyester) reinforces the structure, preventing tears even under heavy pressure.

3. Energy Absorption Meets Durability

When a ship collides, the fender compresses, converting kinetic energy into heat (via internal friction in the rubber layers). This controlled compression protects both the ship and the dock—no more bent metal or cracked concrete.

Fun Fact: The largest super arch rubber fenders measure 2 meters in height and 4 meters wide—built to handle 50,000-ton tankers moving at 8 knots.

🌟 Why Super Arch Fenders Beat the Competition

Traditional fenders (like cylindrical or foam-based models) have their uses, but super arch fenders are the clear winner for modern ports. Here’s why:

1. Superior Protection for All Vessels

Whether you’re docking a 500-ton ferry or a 300,000-ton supertanker, super arch fenders adapt to the ship’s shape. Their curved design cradles the hull, reducing scratches and dents by 80% compared to flat pads.

2. Long-Lasting & Low-Maintenance

Made from marine-grade rubber, these fenders resist saltwater corrosion, UV rays, and ozone damage. A quick rinse with fresh water after use keeps them in top shape—no rust, no rot, no endless repairs.

3. Cost Savings That Add Up

Yes, they cost more upfront than basic fenders, but the ROI is huge:

- Fewer repairs: Save $100k+ per year on hull/dock fixes.

- Less downtime: Keep docks operational 95% of the time.

- Insurance discounts: Many insurers lower premiums for ports using certified collision protection.

4. Eco-Friendly by Design

Rubber fenders are 100% recyclable, and their energy-absorbing properties reduce the need for heavy-duty repairs that harm the environment. No more spilled fuel or toxic runoff—just smooth, safe operations.

Real-World Win: The Port of Singapore upgraded to super arch fenders in 2020. In one year, collision-related damages dropped by 65%, saving $4.8M in repairs and lost revenue.

🌊 Where Are Super Arch Rubber Fenders Used?

- Busy Harbors: Protecting cruise ships, tankers, and container vessels at major ports.

- Industrial Docks: Shielding oil rigs, LNG terminals, and cargo storage facilities.

- Military Bases: Safeguarding warships and supply vessels during docking.

- Private Marinas: Keeping yachts and sailboats safe in crowded waterfront areas.

🚢 Top Benefits of Super Arch Rubber Fenders (Beyond “They Work”)

- Speed: Install in hours—no heavy machinery needed.

- Versatility: Works in shallow water, deep harbors, or even floating docks.

- Customizable: Available in sizes from 1m to 3m tall, with custom shapes for unique vessels.

🔍 People Also Ask (Related Questions)

- “What’s the difference between super arch fenders and regular rubber fenders?”

Regular fenders (like flat pads) are thin and rigid, offering minimal impact absorption. Super arch fenders use a curved, multi-layered design to distribute force, making them ideal for large ships and high-traffic ports. - “How long do super arch rubber fenders last?”

With proper maintenance (rinsing, occasional inspections), they last 10–15 years—even in harsh saltwater environments. - “Are super arch fenders expensive?”

Initial costs are higher than basic fenders, but they pay for themselves in 2–3 years through reduced repairs, downtime, and insurance savings. - “Can I install super arch fenders myself?”

Basic installation is possible, but we recommend partnering with certified marine engineers to ensure proper sizing and placement for your specific vessel type. - “Do super arch fenders work in cold climates?”

Absolutely. Marine-grade rubber resists freezing and cracking, making them reliable in Arctic ports or winter conditions.

🛠️ Ready to Protect Your Fleet (and Your Bottom Line)?

Super arch rubber fenders aren’t just a “nice-to-have”—they’re a necessity for modern ports and shipyards. Whether you’re managing a bustling harbor or a private marina, these fenders turn collisions from disasters into minor hiccups.

Need help choosing the right size or quantity for your operation? Our team of marine experts has 20+ years of experience—we’ll design a custom solution to fit your vessels, budget, and port layout.