Ocean Defender Introduction

( Netless Foam Fender )

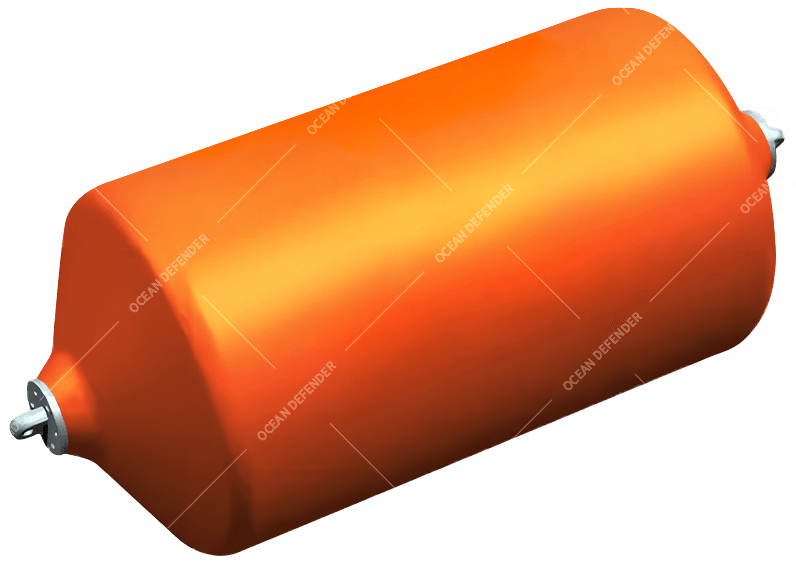

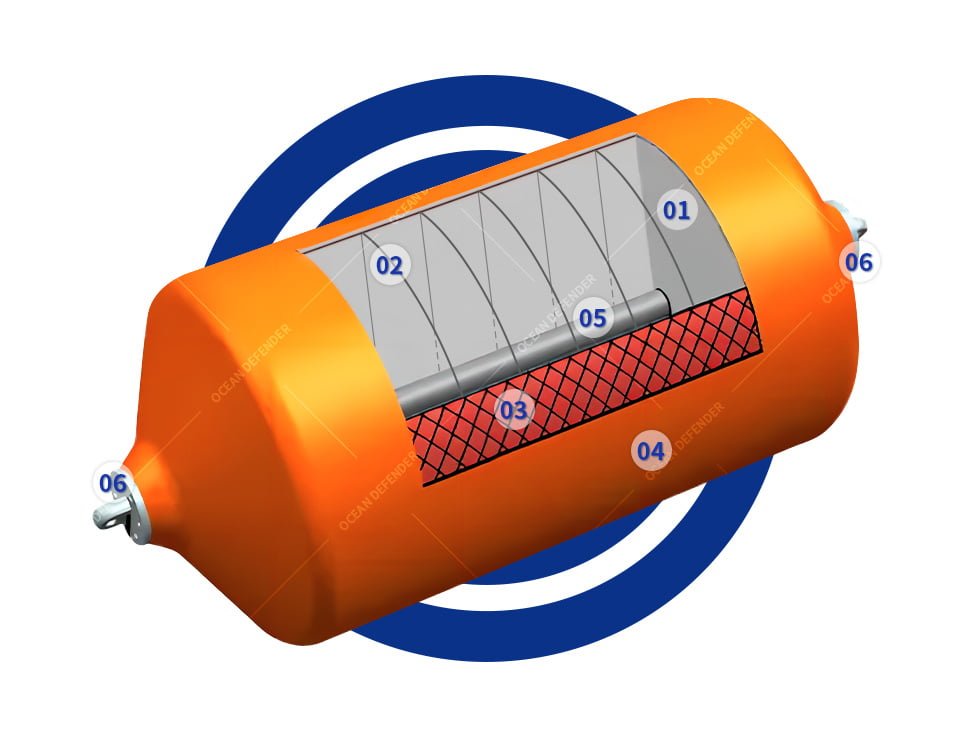

NANHAI is the exclusive manufacturer of “Ocean Defender” (Netless foam fender) and “Ocean Armored-Defender” (Net foam fender) which have the world today leading & professional high-tech raw materials and unique production technology.Ocean Defender with supreme functionality widely used in mooring or berthing fields in the world.Hull pressure is extremely low, making Ocean Defender gentle on ships but also non-marking,become the preferred foam fender product of multinational navies.Main construction includes:

- 100% fully closed cell foam core body.

- High-tech polyurethane coating.

- Heavy Duty Central Axis.

- High Strength End Flange.

- Advanced Steel 360° Swivel End Fittings.

- Reinforced nylon tire cord skeleton layer.

Related Products

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Port Infrastructure, Floating Technology, Ship to Ship, Marine Prevention, Shipyard Solution, Offshore Project etc.

Ocean Defender “Unique” Structure

Ocean Defender pays attention to each detail of fender structure

01 Fully closed cell foam core

As core functional part of foam fender choose supreme PE material,provide fender advanced energy absorption and low reaction force,making the Ocean Defender own superior performance in safety, durability and function.According to different working conditions have a variety of capacities to choose.

02 Laminated foam core (Non-Winding)

Fender adopt foam lamination production technology.This structure can exert its maximum mechanical performance and ensure the superiority of energy absorption and reaction force.Most manufacturers use winding process, fender will be deformed during application, which will affect energy absorption and reaction force at the same time.

03 Reinforced nylon tire cord skeleton layer

Multi-layer cords (Premium Quality) are winding during the polyurethane spraying process, and the cord layers play a role of skeleton support, which strengthens the “Outer Jacket” of foam fender again.This advanced skeleton process extremely durable to all types of weather, forces, and marine conditions.

04 Black Technology Coating

Ocean Defender using our exclusive research and development of Black Technology Materials (Non-marking Polyurethane) sprayed on the outside of foam core,which like wearing a strong and elastic armor to protects foam core permanently.

05 Heavy Duty Central Axis

Ocean Defender equipped with the heavy-duty central axis as standard which plays the role of supporting and installing foam fenders.Since the center axis is installed inside the fender, its actual strength cannot be detected, and it is also an important part of avoiding pitfalls.

06 High Strength End Flange

End flange is the important safety connection point which is made of superior-quality steel to ensure the safety and long-term application of foam fender hanging.

07 360° Swivel End Fittings

The fender installation chain and fender flange are directly connected by 360° swivel ring and shackle, which equipped with strengthening accessories and made of advanced tensile strength steel.

Ocean Defender “Black-Technology-Material”

This Black Technology Material used by Ocean Defender may subvert your perception of foam fenders.

You can imagine the result of a watermelon falling from height, but if the watermelon is sprayed with our black technology material and falls from the height of 100 meters, can you still imagine the result?

The almost indestructible coating of Ocean Defender is made of Polyurea,one Black Technology Material ( Polyurea is a branch of polyurethane ). This Black Technology Material is independently developed by us which have very important properties like:extremely strong, stretchable, flexible, anti-deformation, anti-corrosion,UV resistance etc.

The polyurea coating is a direct protective measure for foam core, so the quality and performance of polyurea coating directly determine the strength and service life of foam fender, which is a pitfall point that users need to pay special attention to.

Ocean Defender “Authenticity” Superiority

After years of product R&D combined with actual product applications and user feedback, Ocean Defender reflects the excellent product performance, and truly exerts its ultimate reliability, safety and stability,empowering world green and smart docks.

- Superior energy absorb and low reaction force.

- Lower reaction force than rubber fender & keep high energy absorption.

- Compression & recovery efficiency golden ratio.

- Extrely low hull pressure,non-marking polyurethane coating.

- Anti-burst,anti-sinking, ultimate security.

- Remain functions under accidental damage.

- Excellent anti-ultraviolet light (UV) resistance.

- Resistance to acid, alkali and salt and marine biology corrosion.

- Resist all kinds of rough marine environments (Tropic & Frigid Zone).

- Material and technical process determine long service life.

- Suit all sites no matter small or large tidal changes.

- Customization of fender size and shape.

Application And Leading Extended Field

Cruise ships|Container vessels|Bulk cargo|RoRo and ferries|Oil and gas tankers|General cargo|Navy berths|Ship-to-ship transfers

Dock or Ship Berthing

Ocean Defender apply in dock berhing is the most common application scenario.Show the excellent performance.

STS Ship to Ship

During ship to ship operation,as protective device foam fender or pneumatic fenders are usually used.

Buoyancy Project

Ocean Defender can be used as the buoyancy device to complete transportation and installation for offshore project.

Bridge Blocking Project

Ocean Defender cooperate with other device to form a group of floating unit apply in bridge blocking project.

Ocean Defender Installation Diagram

Multiple Capacity Performance Parameter

| Fender Size D x L [mm] | Energy [kNm] | Reaction [kN] | Weight [kg] |

| 500×1000 | 9.2 | 63.8 | / |

| 700×1500 | 28 | 136 | / |

| 1000×1500 | 49 | 174 | / |

| 1000×2000 | 74 | 255 | / |

| 1200×2000 | 99 | 289 | / |

| 1350×2500 | 164 | 421 | / |

| 1500×3000 | 249 | 574 | / |

| 1700×3000 | 306 | 627 | / |

| 2000×3500 | 493 | 858 | / |

| 2000×4000 | 590 | 1020 | / |

| 2500×4000 | 848 | 1189 | / |

| 2500×5500 | 1304 | 1797 | / |

| 3000×4900 | 1509 | 1760 | / |

| 3000×6000 | 1990 | 2259 | / |

| 3300×4500 | 1537 | 1654 | / |

| 3300×6500 | 2596 | 2723 | / |

| 4500×6000 | 3760 | 2976 | / |

| Fender Size D x L [mm] | Energy [kNm] | Reaction [kN] | Weight [kg] |

| 500×1000 | 12 | 83 | / |

| 700×1500 | 36 | 117.5 | / |

| 1000×1500 | 64 | 226.5 | / |

| 1000×2000 | 96 | 332 | / |

| 1200×2000 | 129 | 377 | / |

| 1350×2500 | 213 | 548 | / |

| 1500×3000 | 324 | 747 | / |

| 1700×3000 | 398 | 816 | / |

| 2000×3500 | 641 | 1117 | / |

| 2000×4000 | 768 | 1328 | / |

| 2500×4000 | 1104 | 1548 | / |

| 2500×5500 | 1698 | 2340 | / |

| 3000×4900 | 1965 | 2292 | / |

| 3000×6000 | 2592 | 2983 | / |

| 3300×4500 | 2001 | 2153 | / |

| 3300×6500 | 3381 | 3547 | / |

| 4500×6000 | 4901 | 3875 | / |

| Fender Size D x L [mm] | Energy [kNm] | Reaction [kN] | Weight [kg] |

| 500×1000 | 15 | 104 | / |

| 700×1500 | 45 | 222 | / |

| 1000×1500 | 80 | 283 | / |

| 1000×2000 | 120 | 415 | / |

| 1200×2000 | 161 | 471 | / |

| 1350×2500 | 266 | 685 | / |

| 1500×3000 | 405 | 934 | / |

| 1700×3000 | 498 | 1020 | / |

| 2000×3500 | 801 | 1396 | / |

| 2000×4000 | 960 | 1660 | / |

| 2500×4000 | 1380 | 1935 | / |

| 2500×5500 | 2122 | 2924 | / |

| 3000×4900 | 2456 | 2865 | / |

| 3000×6000 | 3240 | 3736 | / |

| 3300×4500 | 2502 | 2692 | / |

| 3300×6500 | 4226 | 4434 | / |

| 4500×6000 | 6126 | 4884 | / |

How To Avoid Pitfalls

How users to choose superior performance foam fender.

Foam fenders have a wide range of applications and a broad product market, so there are a large number of product manufacturers, but the quality on the market is uneven. In order to reduce costs, the products lose their basic performance of energy absorption and reaction force, and a large number of accidents caused damage to berthed vessels or impacts on piers. At the same time, due to the high value of the foam fender itself, users suffered huge economic losses.

For Example:

- Foam fender produced according to lower tolerances to reduce costs.

- Misleading customers on the basis of foam core density, combined with price (Learn More).

- Winding structure foam core: low cost, poor performance of energy absorption and reaction force (Used by most manufacturers).

- The foam core is made of mixed density material, which has low cost and low performance.

- The foam core is directly filled with waste materials, which loses the basic performance of foam fender.

- Using poor qualitycentral axis, low cost, low strength, easy to break.

- Central axis is filled with scrap steel sand/cement to meet the weight requirements of customer.

The above situations exist alone or at the same time. Customers must understand clearly before making a decision when purchasing, otherwise it will bring you a large economic loss. Find us to know more.

Low-quality foam fenders may be an advantage in terms of purchase cost, but in practical applications, foam fenders essentially test its energy absorption and reaction performance, safety and long-term stability. If the long-term application cost is considered, low-quality foam fenders have no any advantage, which will directly lead to economic losses for customers and threaten the safety of personnel/ships/docks.

- Inferior foam fender have the problem of foam core collapsed, because foam core material is not properly selected (waste/mixturematerial), cannot withstand high-intensity repeated impacts, and foam fender will have non-elastic deformation, resulting in performance degradation, or even loss of performance and service life greatly reduced,damage to ships and docks.

- Inferior foam fender have the problem of Polyurethanecoating Due to the insufficient thickness and quality of Polyurethane reinforcement layer on the surface of foam fender, and the unreasonable layout of tire cord layers, the force on the surface is relatively concentrated and will be cracked. After long-term application, the foam core absorbs moisture and performance declines,the cracking gap will become larger and larger, affecting fender service life.

- Inferior foam fenderhave the problem of central axis damaged. The central axis with low strength will be bent,deformed or even broken during repeated compression. The foam fender loses its supporting function. If the inspection is not timely, it will bring direct economic losses.

The three most important parts of foam fender are: Foam Core, polyurethane Coating, and Central Axis. Customers must pay attention to the quality problems of these three parts when choosing, so as to avoid unnecessary losses.

Foam Core: The foam core is the key factor to reflect the foam fender performance.The closed-cell foam core should be selected. At the same time, according to different expansion ratios, the foam density will be different. It is necessary to communicate with the manufacturer according to the actual application.

Polyurethane Coating: It is the protective layer of foam fender, which has the effect of dispersing the force. The quality and thickness of polyurethane coating can resist the damage to foam fender caused by friction. At the same time, attention should be paid to the structural layout of tire cord layer.

Central Axis: The central axis is the key point to support the foam fender. The material and strength of the central axis determine the service life of foam fender. Central axis’s reasonable size and strength can greatly improve the overall cost performance of the product.

NANHAI company has been developing and technically researching on foam fender products for 16 years, and has accumulated a large amount of product and application experience. It can provide customers with a full range of foam fender technical support, guide customer selection of fender, complete fender layout solutions and installation guidance program, etc.

- Provide customers with economical, safe, reliable and extremely stable foam fender.

- Standard type foam fender production.

- Structure optimization and production of non-standard foam fender.

- R&D foam fender under extreme climate/condition applications.

- Installation instructions for foam fender (on-site/off-site).

- Fender installation layout specification and solutions.

- Quick response mechanism of after-sales service.

- Inventory system to meet the emergency delivery time.

Would you like to know more about Rubber Fender?

Contact us now!

NANHAI Other Marine Industrial Forms

The development of NANHAI during the past 20 years has involved many maritime fields, providing global customers with overall solutions for Berthing, Mooring, Ship to Ship, Ocean Wind Power, Deep-Sea Farming, Buoyancy and Salvage, Bridge Blocking, Ship Launching, Dock Caisson Moving etc.