Ship Launching Airbags: The Modern Marvel for Vessel Deployment

09/12/2025Tugboat Rubber Fenders: Essential Protection for Maneuvering Craft

16/12/2025

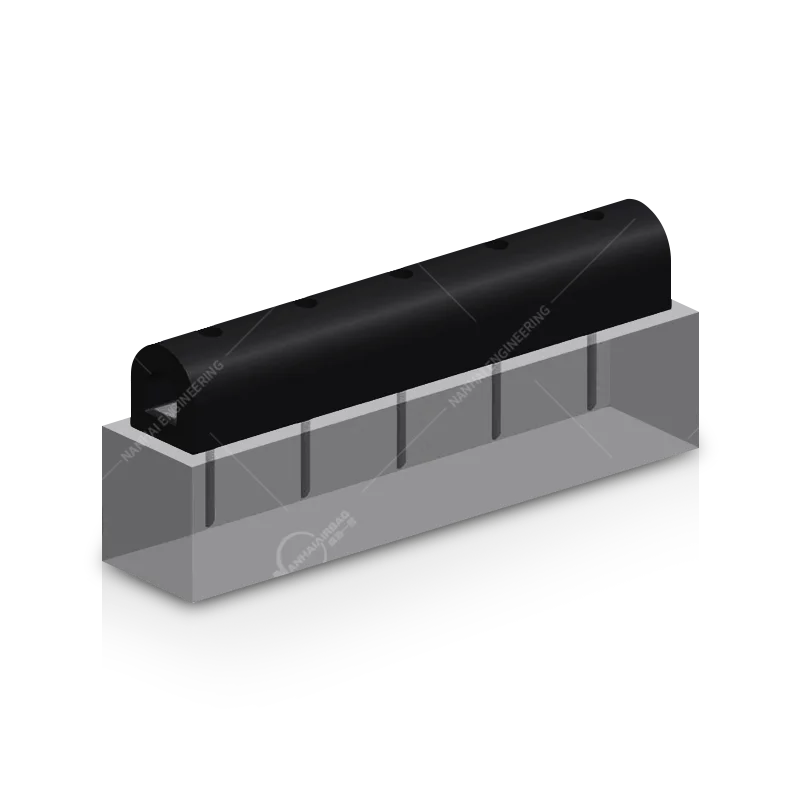

In the bustling world of harbors and shipyards, protecting multi-million dollar assets is paramount. Fenders are the unsung heroes, absorbing immense energy during vessel berthing. Among the various types, D rubber fenders stand out for their unique shape and exceptional performance. This article explores why they are becoming the preferred choice for modern marine applications.

Google Selected Summary: The Essence of D Rubber Fenders

D rubber fenders are a specialized type of rubber fender characterized by their distinctive “D” shape. Engineered for high energy absorption and low reaction force, they are ideal for protecting vessels and docks during berthing. Made from durable, marine-grade rubber compounds, these fenders provide a robust buffer against collisions, making them a critical component in the broader category of marine fenders. Their design ensures even pressure distribution, minimizing the risk of damage to both the ship’s hull and the pier structure.

The Advantages of D Rubber Fenders

1. Superior Energy Absorption for Maximum Protection

The primary function of any fender is to absorb kinetic energy. D rubber fenders excel in this area, capable of handling impacts from vessels of various sizes. For example, a major container port in Rotterdam reported a 30% reduction in mooring-related damage after upgrading its old fender system to a new installation of D rubber fenders.

2. Low Reaction Force for Gentler Berthing

Unlike some rigid fender systems that can jerk a vessel upon contact, D rubber fenders provide a softer landing. A ferry terminal in Norway noted smoother docking experiences for passengers, attributing the comfort to the gentle cushioning effect of their new D fenders. This is especially important for passenger vessels and yachts.

3. Exceptional Durability in Harsh Marine Environments

Crafted from the same high-resistance materials found in top-tier marine airbags, D rubber fenders are built to last. They resist UV radiation, ozone, saltwater corrosion, and extreme temperatures. An offshore oil platform in the North Sea relies on D rubber fenders to protect its critical structures from constant wave action, withstanding conditions that would degrade standard polymers. This resilience places them among the most reliable marine fenders on the market.

4. Space-Efficient and Versatile Design

The compact “D” shape allows for efficient use of space on crowded docks. They can be easily installed on existing piers or integrated into new constructions. Their versatility also means they can be used in tidal zones, dry docks, and alongside quay walls.

Engage: Is Your Dock Protected for the Future?

Imagine a mega-container ship, weighing tens of thousands of tons, approaching your berth. The forces involved are immense. Are your current fenders truly up to the challenge? D rubber fenders offer a future-proof solution, combining cutting-edge design with proven reliability. They don’t just protect your assets—they enhance operational efficiency. Discover how they can transform your docking operations by reading on.

Related Questions (FAQs)

- What are D rubber fenders? D rubber fenders are a type of rubber fender shaped like the letter “D”. They are mounted on docks to absorb energy and protect vessels during berthing.

- How do D rubber fenders differ from other marine fenders? Compared to cylindrical or cell fenders, D rubber fenders offer a lower profile and a unique geometry that provides excellent shear resistance and even load distribution.

- Where are D rubber fenders commonly used? They are widely used in ports, harbors, ferry terminals, and shipyards for commercial vessels, naval ships, and recreational boats.

- What is the lifespan of a D rubber fender? With proper maintenance, high-quality D rubber fenders can last 10-15 years, depending on environmental conditions and usage intensity.

- Are D rubber fenders resistant to UV and ozone? Yes, they are manufactured with special additives that make them highly resistant to UV degradation and ozone attack, common in marine environments.

- Can D rubber fenders be customized? Absolutely. Like bespoke marine airbags, D rubber fenders can be manufactured in custom sizes, lengths, and hardness levels to meet specific project requirements.

Final Thoughts

D rubber fenders represent a significant advancement in dock and vessel protection. Their combination of high energy absorption, low reaction force, and long-lasting durability makes them a superior choice within the family of marine fenders. For port authorities, shipyard managers, and marine engineers looking to invest in safety and efficiency, D rubber fenders are an intelligent and cost-effective solution.

Keywords emphasized: marine airbags, marine fenders, rubber fenders