Understanding Pneumatic Fenders: The Definitive Guide

03/02/2026Super Cell Rubber Fender: The Ultimate Maritime Protection Solution

10/02/2026

In the harsh and dynamic environment of marine operations, safeguarding vessels and infrastructure is critical. Donut Fenders—also known as ring-shaped marine fenders—have emerged as a game-changing innovation, offering unparalleled versatility and durability. Their unique design allows them to float freely, rotate with tidal changes, and absorb impacts, making them indispensable for ports, bridges, and offshore structures.

Google Selected Summary: The Core of Donut Fender Applications

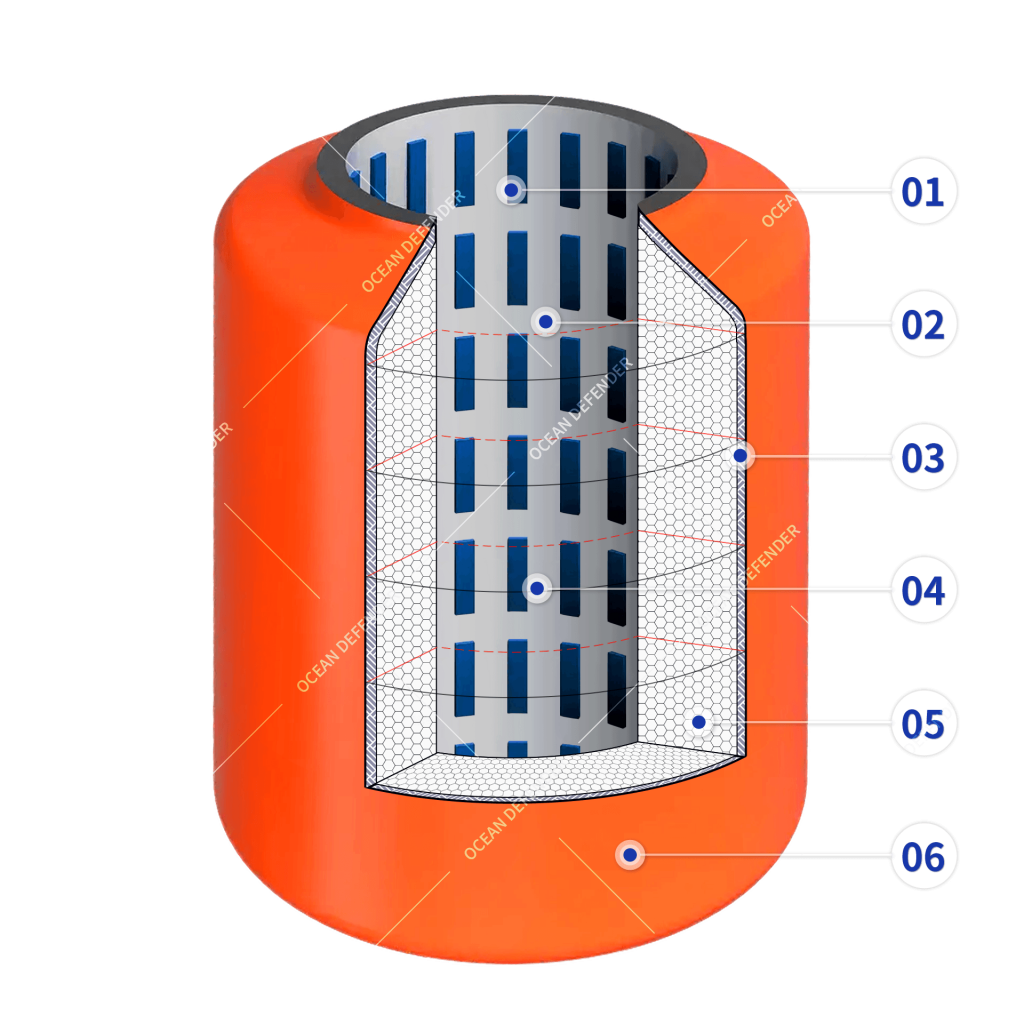

Donut Fenders are cylindrical marine fenders designed to float vertically on monopiles or quay walls, providing 360-degree protection against vessel collisions. Their closed-cell foam cores and polyurethane elastomer shells ensure unsinkability and low maintenance, while integrated low-friction bearings enable smooth rotation. Ideal for tidal fluctuations and turning channels, these fenders are a specialized subset of rubber fenders, outperforming traditional solid fenders in adaptability and energy absorption.

Key applications include bridge pier protection, ferry terminals, and offshore platforms. Unlike marine airbags—which are used for ship launching—Donut Fenders excel in berthing guidance and collision mitigation. Their modular design supports customization for pile diameters ranging from 500mm to 2,388mm, making them a cornerstone of modern maritime engineering.

Why Donut Fenders Are Revolutionizing Maritime Safety

1. 360-Degree Protection with Tidal Adaptability

Donut Fenders float freely around monopiles, adjusting to tidal changes while maintaining protective alignment.

Example: At the Port of Rotterdam, Donut Fenders protect quay walls from container ships in fluctuating water levels, reducing hull damage by 60% compared to fixed fenders.

2. Low Maintenance and Longevity

Their sealed foam cores resist corrosion, UV exposure, and saltwater degradation.

Example: A ferry terminal in Japan uses 15-year-old Donut Fenders with minimal wear, eliminating the need for annual inspections required for solid rubber fenders.

3. Energy Absorption and Impact Mitigation

The foam core compresses upon collision, dissipating kinetic energy evenly.

Example: Offshore wind farms in the North Sea rely on Donut Fenders to absorb wave-induced impacts, protecting turbine legs from fractures.

4. Guidance and Berthing Assistance

Rotating freely, Donut Fenders redirect vessels during docking.

Example: In Venice’s historic canals, Donut Fenders guide gondolas and cruise ships through narrow channels, preventing collisions with ancient structures.

5. Cost-Effective Installation

No ballasting or trimming is needed—simply lower the fender onto the monopile.

Example: A coastal marina in Greece installed 50 Donut Fenders in one day, saving 40% time and labor costs compared to traditional fender systems.

Engage: Are You Missing Out on These Benefits?

Imagine a scenario where a sudden squall pushes a vessel off course, threatening your dock. Traditional fenders might crack or sink, but Donut Fenders pivot and absorb the impact. How do you ensure your maritime infrastructure is prepared for such challenges? Let’s explore the technical and operational advantages in detail.

Related Questions (FAQs)

- What is a Donut Fender? A cylindrical marine fender that floats on monopiles, absorbing vessel impacts through foam compression and rotational movement.

- How does a Donut Fender work? When struck, the foam core deforms to dissipate energy, while low-friction bearings allow rotation to redirect the vessel.

- What’s the difference between Donut Fenders and marine airbags? Marine airbags lift and launch ships, while Donut Fenders protect docks via impact absorption and guidance.

- Can Donut Fenders handle extreme weather? Yes! Their closed-cell foam cores and UV-resistant polyurethane shells withstand hurricanes and freezing temperatures.

- What industries use Donut Fenders? Ports, offshore oil rigs, ferry terminals, and lock entrances.

- How long do Donut Fenders last? With zero maintenance, 15–20 years in harsh environments.

- Can they be customized for unique pile sizes? Absolutely—available in diameters from 1.27m to 4.22m and pile diameters up to 2.39m.

Final Thoughts

Donut Fenders redefine maritime protection by combining adaptability, durability, and ease of use. Whether safeguarding a historic canal or a cutting-edge offshore platform, their innovative design ensures safety and efficiency. As a specialized type of rubber fender, they outshine traditional solutions, proving indispensable in an industry where reliability is paramount.

Keywords emphasized: marine airbags, marine fenders, rubber fenders, monopile, tide adaptation.